What Rising Demand for Silicon Wafers Means for Manufacturers

As someone involved in manufacturing ruggedised inspection equipment, you’re no stranger to the demands of the semiconductor industry. According to a recent report from SEMI, global silicon wafer shipments rose by 6% in Q3 of 2024, signalling robust growth and underscoring the critical role of wafer inspection equipment. This increased demand isn’t just about scaling production; it’s about supporting semiconductor manufacturers with solutions that ensure quality and consistency while keeping up with accelerated production cycles. For companies like yours, the challenge is clear: developing ruggedised systems that can endure high-volume, high-speed production environments while maintaining precision.

Increasing Demand Calls for Enhanced, Specialised Computing

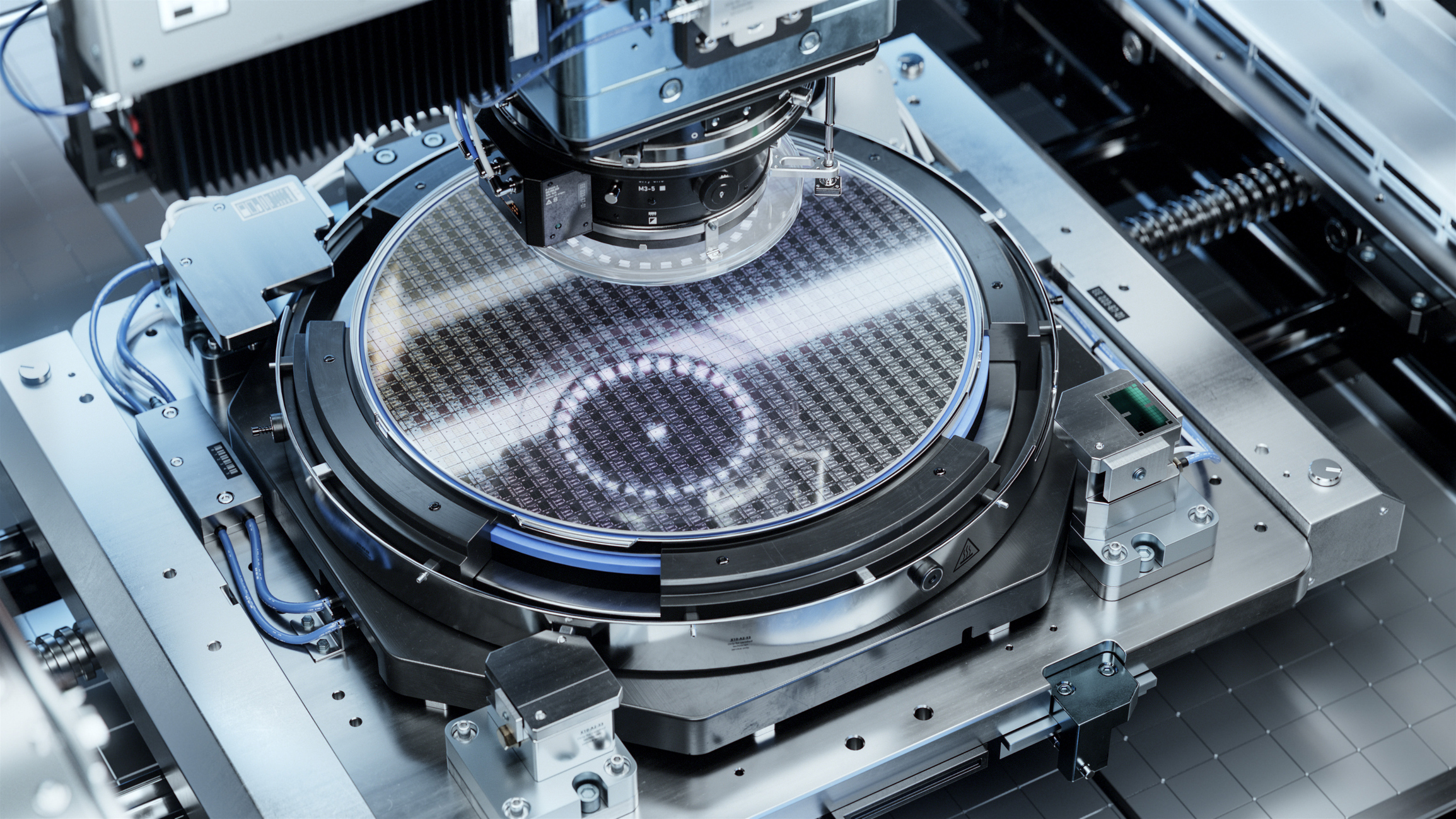

As semiconductor technology advances and track widths shrink to extremely low levels, such as 3nm, the need for highly accurate inspection becomes critical. At these dimensions, even the smallest defect can affect performance and yield.

To meet these stringent requirements, inspection equipment must utilise high-performance computing solutions capable of analysing complex, high-resolution data in real-time. As wafer production scales, these systems require specialised computers engineered not only for processing power but also optimised thermal management to cope with the increasing Thermal Design Power (TDP) demands of next-generation CPUs and GPUs. This combination enables manufacturers to perform detailed, precise inspections, ensuring quality and consistency across thousands of wafers each day, even at such minute feature sizes.

Adapting for the Rigours of High-Throughput Environments

The shift towards greater automation and faster production cycles in semiconductor manufacturing places added demands on inspection equipment. In a cleanroom environment, where dust and temperature fluctuations are controlled, the primary challenge lies in having specialised computing systems engineered to handle high-performance components that support the required processing levels.

These systems must also be designed and built to maintain peak performance over extended periods, effectively managing the heat generated by high-performance CPUs and GPUs. Using purpose-built components with optimised cooling solutions ensures reliability and consistent operation, enabling uninterrupted performance and accuracy without disruption.

Real-Time Edge Computing for Efficient Inspections

With wafers becoming increasingly complex, your clients are relying more on real-time data processing to identify and rectify defects instantly. Integrating smart edge computing capabilities into your inspection systems can enable immediate, on-site data analysis, ensuring faster throughput without compromising accuracy. This edge computing support also reduces reliance on cloud connectivity, allowing your equipment to operate autonomously and minimise disruptions on the production floor.

Supporting Precision in a Thriving Market

For manufacturers of inspection systems, the growth in silicon wafer demand translates into an urgent need to produce equipment capable of operating in high-demand environments. Building ruggedised systems requires investing in higher-quality materials, advanced cooling systems, and vibration-resistant designs to withstand production stresses. However, this also positions you to provide added value to semiconductor producers who are increasingly focused on reliability, efficiency, and uptime.

Embracing highly customised computing solutions isn’t just about creating equipment that can endure the demands of challenging conditions—it’s about enabling semiconductor manufacturers to achieve new levels of precision, efficiency, and scalability in a rapidly expanding market. By focusing on durability, high-performance computing, and real-time edge capabilities, you can meet the increasing demand in semiconductor production and help your clients stay ahead in a competitive industry.

Delivering end-to-end, like no one else.

With advanced cooling systems, vibration-resistant designs, and custom solutions designed to support the high-throughput requirements of semiconductor environments, Captec is ideally placed to help you tackle the unique challenges of your environments.

With decades of expertise, Captec offers a robust technology portfolio adapted to meet your specific performance, reliability, and functionality needs – whether you require standard, modified, or fully custom units. We understand the challenges of managing technical assets in advanced manufacturing, including Obsolescence Management, Change Management, and Revision Control. Captec is here to alleviate these pressures, helping your organisation stay ahead of technical advancements and streamline operations.

Discover how we can support your goals on our Machine Vision web page, or let’s discuss your requirements.