Racks for Rail: The Importance of Selecting the Right Integration Partner

Racks for Rail: The Importance of Selecting the Right Integration Partner

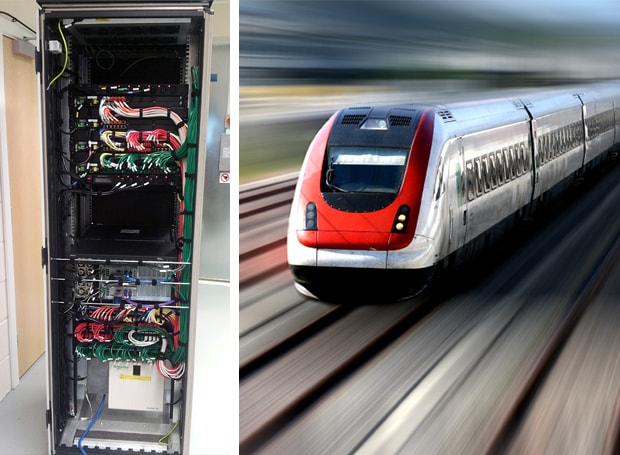

Racks for rail applications come in all shapes and sizes. Some are commercial products, some are modified versions of commercial products and some are fully bespoke. Depending on the application, location and install environment, a number of variables need to be considered in order for the potential of the solution to be fully realised.

Having personally worked on control room, trackside and high-redundancy solutions, it has been clear compliance and documentation are only pieces of the puzzle. The complexity of rail applications means integration partners must have a much broader skillset, and be able to support customers throughout validation, delivery and installation. End-to-end capabilities and task ownership are essential to remain in control, on schedule and on budget, in what can be a technically and commercially challenging area. As can be seen from the images of past projects, solutions can differ greatly and by no means does one size fit all.

Understanding technology roadmaps and manufacturer offerings in both the commercial and industrial markets enables the correct balance between cost, component life and availability to be struck. Having knowledge of rack enclosures and the capabilities and limitations of environments ensures components deliver the performance and reliability required. And understanding how to incorporate the correct levels of protection and redundancy to ensure the required availability and continued operation allows solutions to deliver the value and performance needed for lifespan needed.

So, how do you navigate these complexities and stay on track (forgive the pun)?

Having dedicated internal integration capabilities is a challenge often reported by customers integrating racks for rail applications. As is having critical resources step in to build racks on occasion. Finding a trusted integration partner who can work with you from the outset to help you steer past development pitfalls is key. It is also important to access the ability to bypass development issues, leverage historic designs and provide internal pre-compliance testing to minimise test house fees.

Choose a partner that not only complements your capabilities and allows your teams to concentrate on what they do best, but that also fills knowledge gaps, shortens the time to market and manages the supply chain. This will help ensure projects remain on schedule and on budget, and keep things running fluidly to deliver the flexibility needed to reflect end-user needs and meet changing timeframes.

Finally, select based on the capability to manage your compliance verification, validation and certification, to see your initial concepts through to delivery. Doing so will ensure logistics, method statements, installation guidance and all documentation is provided. This will evidence the design and its operation and ensure you get the equipment installed where and when needed, with minimal interruptions to important services.

If you would like to understand more about how at Captec, we can help your teams deliver solutions where and when you need them, on time and on budget, why not get in touch.